Technology transfer for Developing Countries through Appropriate Technology

Izumi USHIYAMA and Yasuyuki NEMOTO

A priority issue for the 21st century is to assure enough energy and water in the developing countries needed for increased agricultural output and to stop population increases at the same time. Development of devices that utilize renewable energy was conducted with "appropriate technology" in mind as apart of technology assistance scheme to developing countries and achieved fruitful success. In this paper, the authors present several case studies based on our experiences of technical transfer and technical assistance for developing countries which based on a concept of appropriate technology.

Keywords: Developing countries, Appropriate technology, Renewable energy, Technical assistance

|

1. Introduction

Today, the population of the world is six times high as the population at the time of Malthus, known for his dire predictions on population. Earth's population is expected to grow to some 10 billion around the year 2050. The rapid expansion of the population will bring increases in demand for food, explosion in energy consumption, and pollution of the environment. The population expansion has been especially fierce in the last 100 years, growing 3.7 times or by about 4.5 billion people. On the other hand, the growth in the amount of energy used to support this level of human activity is even more phenomenal. Total human energy consumption has increased nine fold in the last century.

Therefore, a priority issue for the 21st Century is to assure enough energy and water in the developing countries needed for increased agricultural output and to stop population increases at the same time.

In this paper, the authors present several case studies based on our experiences of technical assistance for developing countries which were based on a concept of appropriate technology.

2. What is "Appropriate Technology"

From our previous experiences, in technological support for developing countries, there must be a concept that can be called "appropriate technology" (AT) which is best fitted to the environment and conditions of the regional society and in answering the needs there. Therefore, the receptive technologies best fitted to the actual conditions in a given developing country must be selected, transferred, and diffused. But the countries that require technological assistance have multitudes of different conditions and a success of a given technology in a given country does not assure success in a different country.

For example, when planning to pump up water using a wind-powered pump, the combination of windmills and pumps to use will depend on the wind conditions of the site, average precipitation, the conditions of rivers, underground water tables, and other water sources. Furthermore, the technological level of the region, the available types of windmills and pumps, and even the practices and traditions of the local people could affect the design. As described above, AT does not exist as a universal one as there are no common appropriate technologies applicable to all developing countries. Thus, AT can be traditional or modern, small scale or large scale. Its only quality is that it is perfectly appropriate to the individual conditions of the people of the region who need the technology.

3. Case Studies Based on AT

3.1 Wind Powered Water Pumping

Wind energy can be used in applications requiring mechanical or electrical input such as crop drying, threshing and grain grinding, irrigation pumping etc. A wind energy conversion system is especially attractive for agricultural applications because it can provide direct mechanical shaft power that minimizes the conversion losses for pumping, grain grinding etc.

The two year project (from January 1988 to December 1989) in Indonesia, which was managed by Assoc. Prof. T.Pruwadi and agricultural engineering researchers of Gadja Mada University, was concerned with the following six activities.

1) To identify potential areas where wind energy applications can be cost-effective and to select a suitable site within these areas for conducting the project. 2) To design and construct windmills based on adequate information about the existing wind energy potential. 3) To test and evaluate the performance of the windmills. 4) To make appropriate design modifications in the windmill constructions in the windmill construction based on preliminary tests. 5) To test and reevaluate the performance of the re-designed windmills. 6) To introduce the recommended windmill to farmers.

One of the authors Prof. Ushiyama participated in the project as a Japanese counterpart. The financing of the project was provided by The Hitachi Scholarship Foundation in Japan.

In the first year, three different windmill prototypes were constructed and tested; they were two Savonius type windmills with metal frame and with rattan frame, and a Cretan type sailwing windmill (The rotor diameter was 3.5m).

From the results of the field test, the Cretan type windmill had a better performance pumping up 55-60l/min of water compared to the Savonius type windmill that only pumps 39-42l/min of water. The construction cost of the Cretan type windmill is less than that for the Savonius type around 40%.

In the second year, three Cretan type windmills, as shown in Fig.1 have been redesigned and constructed based on the first year's experience.

Fig. 1 Cretan type windmill in central Java.

The water discharge capacity of the windmill operating at a daily average wind speed of 5m/s was 50-60 liters/min. Since wind energy at the site was available 10 hours per day, this means that the windmill can deliver 30 to 36 tons of water per day. This water was enough for irrigation of approximately 1 hectare of garlic crop. As a result, the Cretan type sailwing windmill operated together with a rope type pump is favorable for introduction to the local farmers. (1)

Fig.2 shows the other example of application of windmill for water pumping. This vertical type sailwing windmill was installed in Peru by an A.I.T. researcher, T. Dei in mid 1990s.

Fig. 2 V-axis sailwing windmill in Peru.

3.2 Wind Powered Electric Generation

There are numerous off-grid-areas in developing countries. Considering the back ground of the infrastructure of these countries, it is desirable to introduce a small scale generation of electricity, such as wind, solar, small hydro and so on, rather than a large scale power station.

As a stand-alone power source in developing communities, the authors proposed a small scale wind powered generation system based on a design concept of an AT. The concept was geared toward simplicity, low cost, easiness to maintain, and reliability. Components used can all be affordable off-the-shelf or be manufactured in a workshop with limited facilities. In planning to manufacture a wind driven generator by oneself, the generator is the most essential component. As to it, an automotive alternator was adopted because of availability in any place even in developing countries.

However, in adopting an alternator to the wind driven generator, two major problems must be solved. One is that the rated rotational speed of the alternator is much higher than that of the wind turbine rotor. The other is that an excitation to the alternator has to be done corresponding to the rotational speed of the wind turbine or wind speed.

There are a few cases on excitation methods based on each experience, however, no systematic research had reported. Therefore, the authors made an investigation and evaluation on conventional excitation methods, then, summarized the results systematically. Furthermore, the authors proposed novel excitation current control circuits and the improvement of conventional circuits as follows.

(1) Residual magnetism of the alternator type. This control circuit works exactly, however, it is rather complicated and a lot of parts are needed. (2) Wind pressure switch with a Hall element type. This circuit is simple and the working principle is also simple. Special feature of the circuit is an adaptation of a Hall element that detects magnetism. (3) Centrifugal force switch type. This is the most simple and reliable circuit and suitable for developing countries. (4) Rotational speed detective generator type. This is also simple but it needs separate generator to detect the rotational speed.

The authors confirmed that the excitation current control circuit worked well and also confirmed that a satisfactory agreement was obtained between the rotational speed of the wind turbine rotor and that of the alternator.

From the viewpoint of AT, the automotive alternator may be an excellent compromise as a generator for small-scale wind powered generation.

3.3 Wind and Solar Hybrid Generation System

The authors proposed a portable type wind and solar hybrid (WISH) system. Especially, this system is contained in a small box, so we call this "WISH BOX". The system consists of a small wind powered generator of 300W class and photovoltaic panels of 100W. This unique hybrid generation system is suitable for a small-scale stand-alone power source in an emergency in a stricken district as so called "life-spot", or no-power source districts in developing countries. Through this system, minimum requirement of the electric power output for lighting and information, or radio and mini-television will be provided. These power sources are indispensable for the people living there. In developing countries, this system is useful not only for lighting and information, but also the power source of a refrigerator for vaccines. Moreover, the WISH BOX is characterized by its cleanliness and noiselessness compared with engine powered portable type generators. Therefore, the system is also suitable for the outdoor use such as a power source for camping life.

Fig. 3 shows the picture of WISH box. Fig.4 shows the other example of hybrid system in AIT, named as Savonius type WISH system.

Fig. 3 WISH BOX in Operation. |

Fig. 4 External appearance of the experimental WISH-windmill. |

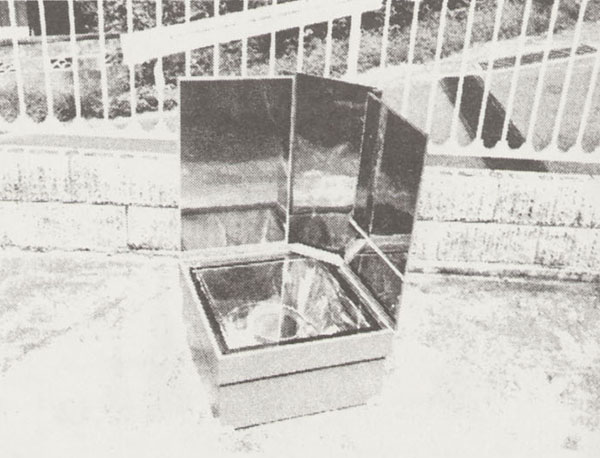

3.4 Solar Cookers

Solar cookers utilize the direct sunlight to cook foods. There are three main categories in solar cookers, i.e. reflecting condenser type, heat box type, and panel type. Regardless of the types, solar cookers do not need any fuels as firewood. Reflecting condenser type solar cookers are mainly used in China and adjacent countries like Tibet and Nepal. The total number of the cookers used in such areas differs with the reports, but probably is more than two hundred thousand. Heat box type solar cookers are popular in the districts where the sun elevation is large as some areas in India and Africa. In India, more than five hundred thousand solar cookers are in use and fifty thousand are sold every year. Back packers prefer panel type solar cookers because most of them are foldable. Also as they are easy to build at a low price, the panel type solar cookers are often used to relieve refugees.

Opinions have been in quite accord that the box type solar cookers are not for the use in Japan. However, the heat-box type solar cookers excel the other types in versatility and ease of use, and if high-performance heat box for the use in Japan is successfully designed, many countries at middle latitudes will also receive the benefits of solar cooking. But by our modification, we now have several heat-box type solar cookers that can cook food even in winter in Japan. Actually, the booster mirror can most effectively reflect the light into the heat box when the sun elevation is 75 degrees which is about the elevation in summer in Japan. The heat box type solar cookers are now mainly used in the area where the sun elevation is high and where people prefer the boiled food. A conventional heat box type solar cooker is simply a well heat-insulated box with a glass lid and a supplementary reflector called booster mirror.

The solar cookers for Japan should not be expensive because we only have less than 200 fine days a year on which we can use solar cookers. Additionally, most Japanese would not use solar cookers if they need too frequent adjustment outside. The followings are features of our latest improved heat-box type solar-cooker.

- No need of adjustment of orientation or angle of booster mirrors in six hours.

- It can boil a liter of water within three hours in winter of Japan.

- Once the temperature reaches 100 degree, it can keep it above 80 degrees for two hours.

- If you adjust the orientation of the mirror frequently, its performance doubles.

- When the booster mirror is folded, its dimension is as compact as 60cm x 60cm x 20cm.

Fig. 5 Various heat box type solar cookers. |

Fig. 6 Our latest heat-box type solar cooker. |

3.5 Biomass Gasified Generation System

The gasification of biomass is mainly classified into two groups based on the process of gasification. One adopts micro-organisms or anaerobic fermentation, and the other, thermal cracking. The reaction of the latter proceeds more rapidly than the former, so it can occur through the gasification of woods and chaffs.

The authors conducted a research and development of the gasification by thermal cracking. Woods, woodchips, wood pellets made from pressed chaffs, rice straw, bagasse (fiber residue from the milling of sugar cane) are derived from agriculture.

Thermal cracking starts to occur when the temperature of woods is increased. Gas whose main components are some hydrocarbon, tar and char are then created. When the temperature exceeds around 300LC, wood can continue to burn its own and char is broken down into CO, CO2 and H2 gases.

In an actual utilization of wood based biomass, one of the problems was tar creation. Tar, which is the aggregate of polymers of a kind of hydrocarbon, changes to liquid with high viscosity and adhesion. Particularly, when it sticks to pistons of engine, it adheres and ignition failure causes. Thus, until now, washing equipment was used for the section between the gasifier and the engine. However, the other problems of increased facility cost and decreased synthetic efficiency are caused. Another problem was quantity of flammable gases. The chemical reactions of char gasification are complicated. The reaction speed depends on the temperature of the gasifier, quality and quantity of the fuel, and quantity and passage time of the air. It is necessary to optimize these conditions to get a higher quantity of flammable gases. Therefore, the problem up to now has been how to eliminate tar at low cost, and how to get more flammable

gases.

In 2000, one of the authors Nemoto and Mr. Erdene from Mongolia conducted an experiment to solve the above-mentioned problems and to optimize the ventilation of the gasifier. Through the experiments, it was found that the tar creation became less and the quantity of flammable gases increased by adopting a downward ventilation system.

An appearance of a small- scale gasifier is shown in Fig.7, which was manufactured by Mr. Erdene, a Mongolian researcher at A.I.T in 2000. Since many of the Mongolian people are nomads and often change their location throughout the year, there are very limited electricity networks in Mongolia. On the other hand, because of dry climate, dried dung from livestock can be easily obtained for fuel. Mr. Erdene studied the use of dried dung as a fuel for nomads using the gasifier and developed it based on the results of the research. Similarly, the technique of biomass gasification is fairly useful and can be suited to the climate, topography and lifestyle of the country.

Fig. 7 A Gasifier for Mongolian nomads.

3.6 Water Hammer Pump

Water hammer pumps or hydraulic ram pumps are simple water pumping devices that are powered by falling water. There is no necessity to use such pumping devices in advanced countries where we can utilize electricity wherever we want. However, there is still strong needs for water hammer pumps in developing countries.

The pump works by using the energy of a large amount of water falling a small height to lift a small amount of that water to a much greater height. In this way, water from a spring or stream in a valley can be pumped to a village or irrigation scheme on a hillside. Wherever a fall of water can be obtained, the hydraulic ram pump can be used a comparatively cheap, simple and reliable means of raising water to considerable heights.

The power required to raise water is proportional to the water's flow rate (q) multiplied by the height (h) through which it is lifted (in a ram pump qxh). Similarly, the power available from falling water is proportional to its flow rate (Q) multiplied by the distance dropped (H): (QxH). A water hammer pump works by transferring the power of a falling drive flow to a rising delivery flow.

Thus, the input power is proportional to drive flow (Q) x drive head (H), and output power is proportional to delivery flow (q) x delivery head (h). In a real system, considering the efficiency (ah), delivery flow rate is as follows.

|

Delivery flow (q) = QHh/,^

|

The hydraulic pump system can only lift a fraction of the flow that drives it. This ratio of delivery head to drive head (h/,g) is typically in the

range 5 to 25.

Fig. 8 shows a demonstrative operation of the simplified water hammer pump designed by T. Dei at Ashikaga Institute of Technology.

Fig. 8 Water Hammer Pump in Operation.

4. Demonstration Project of Ashikaga Institute of Technology

Recently, the global environmental problems became more and more a serious matter of concern among people in the world and AIT also has been devising some practical measures on enlightenment and dissemination of natural energy utilization. This June, we extended "Wind and Sun Square" locating near our campus expecting the following three roles. The first role of the square is an outside experimental field to learn how to make use of the natural energy. The second one is a theme park to enlighten and educate on the environmental problems. And the third one is a workshop to acquire appropriate technologies for supporting developing countries. The total area of the square is 12,000 m2 and it consists of four sub-themes, i.e. wind, sun, water, and wood. In the square as shown in Fig. 9, the all-inclusive small-scale wind turbines, solar panels, scooping pumps, and other devices utilizing the natural energy are on display.

Fig. 9 Natural Energy Square at A.I.T.

In the site, we have a biotope pond as natural ecosystem, a deck made of lumbers from thinning out as an outside classroom, and the natural energy mini museum as exhibition hall. On the first floor of the two-story museum as shown in Fig.10, various micro-scale wind turbines, models of windmills, and other goods about "wind" are displayed.

Fig. 10 Exhibition hall of the Museum.

The second floor is dedicated to solar cookers and each type of representative solar cookers in the world including Chinese reflecting type, Indian heat box type, and American panel type solar cooker for back-packers, etc. are displayed. This square has been the observation site for the visitors from developing countries by the program in the agricultural machine course in Tsukuba International Center of JICA, Asian Rural Institute, New Energy Foundation, etc. since its establishment for six years.

5. Conclusion

In order for technology transferred from developed nations to developing countries to prove useful and be actually "appropriate technology", local needs must be measured, appropriate technology must be applied, maintenance and repair methods for the hardware must be taught, and human resources developed. Established modern technology of the one-size fits all style can be transferred with the hardware and manuals alone. Since "appropriate technology" has numerous variations in the applicability to the locality and demand, it is almost impossible to establish it as a systematic field of study. Even in Japan, it is imperative to have facilities where "appropriate technology" can be studies and implemented in earnest in order to conduct effective international contributions and technological cooperation in the future.

References

- Ushiyama, I. and Pruwadi, T., Development of a Simplified Wind-Powered Water Pumping System in Indonesia, Wind Engineering Vol.16, No.1 (1992) pp.1-9

- Ishiguro, N. and Ushiyama, I., A Design and Performance of Small-scale Wind Driven Generator for Developing Communities, Proceedings of ENERGEX' 93, Vol.III, (1993), pp.407-416

- Onai, Y. and Ushiyama, I., An Experimental Study of The Windmill of Solar Cell Buckets, Proceedings of World Renewable Energy Congress-IV, (1996), Denver, USA

- Morioka, S. and Ushiyama,I., A Windmill of Solar Cell Blades, Proceedings of World Renewable Energy Congress-II, (1992),

- Ushiyama, I. and Nagai, H., Optimum Design Configuration and Performance of Savonius Rotors, Wind Engineering, Vol.12, No.1 (1988)

- Nakajo, Y., Indispensable Requirements to Improve Solar Ovens for the Use in Japan and their Prospect, World Renewable Energy Congress-V, (1998)

|